When we went to Morocco, we could see with our own eyes the process of making leather in one of the most important tanneries in the country. In it, countless pits filled with natural dyes make up a colorful landscape as they take care of the production and coloring of the leather of the lamb, ox, goat and camel.

Traditional leather-making process:

The first step in traditional tanneries is to clean the skin superficially to apply large amounts of coarse salt and let it dry on roofs, so that it loses much of the excess water that has been added previously.

The second part consists of introducing the skins into huge white tanks filled with lime and pigeon droppings, where they are left to rest for several days. This process has two purposes: on the one hand, to finish removing everything that is not skin itself, and on the other to give it firmness.

At that time the process of "cleaning" the skin will be finished, and what will continue will have the purpose of giving it additional properties, such as softness and color. To do this, it will be immersed in the other tanks, which use materials such as fig paste and oils to give softness and tanning, and natural dyes to provide color.

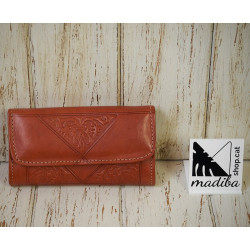

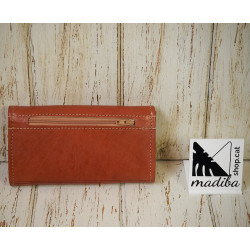

Finally, there will be the drying process, which takes place on the roofs around the tannery. Once the skins are coloured and dry, they will go to the hands of the craftsmen who will transform them into elaborate bags, suitcases, shoes and coats, etc.